Industrial robot

A cloth wheel is installed on the robotic arm and products with irregular and complex surfaces can be polished according to the set motion trajectory. At present, many kitchen and bathroom hardware, decoration, automobile wheel and other industries have begun to use this robot-automated polishing method extensively. By replacing the cloth wheel and polishing paste with a finer grit size on the surface of the product that has been ground in the previous process, the same equipment can achieve the polishing function. Its advantage is that it is suitable for processing medium and large product parts with complex shapes, and can also achieve mirror effects. The disadvantage is that the purchase cost is high and the investment in supporting facilities is also high. It can only be processed in a single piece, with low efficiency. The operation and maintenance are complicated. It cannot handle the inner surfaces of the product such as holes and gaps.

Shot blasting machine

Shot blasting or shot blasting machines can also be used for polishing. They use stainless steel shot media to hammer the surface of metal parts at high speed to increase surface density and achieve the effect of improving surface gloss and brightness. The advantage is that it is suitable for medium and large parts, and can also handle complex curved surface cavities. The disadvantage is that the polishing roughness is high, which can only increase the gloss and brightness, but cannot achieve a mirror-like polishing effect. In addition, it can only be used for surface polishing of product parts made of metal.

Magnetic polishing machine

Magnetic polishing machine integrates the finishing and polishing processes into one. It uses the high-speed rotation and rolling of stainless steel needles to impact the surface of the workpiece. It removes burrs, scale, oil and impurities while improving the surface brightness of the product, achieving the purpose of polishing. The advantages are high efficiency, no loss of consumables media, and low investment. The disadvantage is that the number of processes is small, it is only suitable for small product parts, and the surface roughness after polishing is relatively high.

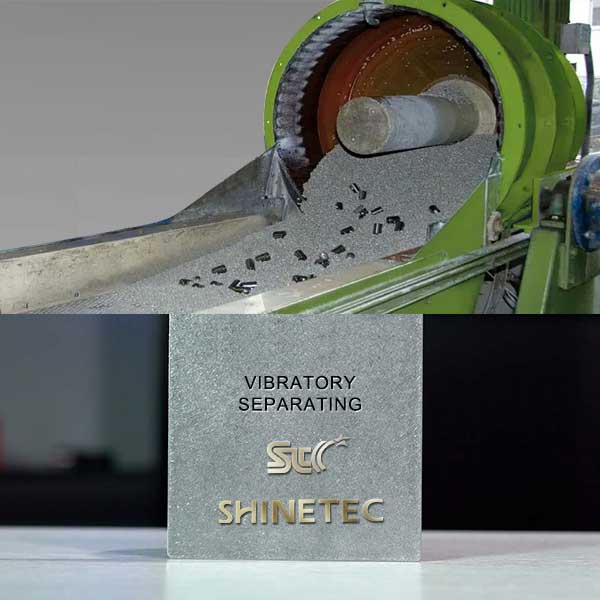

Tumbling polisher

It can also be called a mass polishing machine, polishing tumbler. Based on the rough finishing of descaling and deburring in the previous process, by replacing different polishing media, the roughness of the product surface can be reduced and the brightness can be improved. Abrasive media for polishing are generally usedporcelain polishing media, high-density porcelain media (In fact, this is also a type of porcelain, but the alumina content in it is higher than that of common porcelain media, can reach about 95%, so the density is higher than that of common porcelain media), white corundum polishing media, chrome corundum polishing media, stainless steel polishing media. The principle is to use high-density, high-hardness tumbling media to hit the surface of metal products to change the tightness of the arrangement between grains. At the same time, the micro-powder contained in the polishing media is used to perform micro-cutting on the surface, reducing roughness and improving brightness and gloss. There is also a polishing method commonly known as polishing, which is to use barrel tumbling polishing machine uses plant bio-degradable such as wood chips, bamboo chips, corn cobs, and walnut shells. It uses the coarse fibers on the surface of this material to simulate the cloth wheel used for manual polishing, and with the polishing paste, it passes Dozens of hours of slow and micro-finishing achieve a mirror-like effect. The advantage of rotary tumbling polishing is that it has a wide range of applications, large batches, and high efficiency. It can be used for product parts with various special shapes and complex surfaces. The materials can also be metal and non-metal materials. The operation is simple and convenient. The disadvantage is that the polishing effect cannot reach the mirror state of a manual cloth wheel. The smooth polishing method can only achieve an effect close to a mirror surface at best.

3. Chemical polishing.

Chemical polishing is a method that relies on the chemical corrosion of chemical reagents to selectively dissolve uneven areas on the surface of the product to eliminate oxide scale and etch and level it. Using strong acid or alkaline solutions such as sulfuric acid, nitric acid, phosphoric acid, hydrofluoric acid or sodium hydroxide, the principle is that the convex parts on the surface of the metal parts have a different electrode potential than the concave parts in the solution, resulting in different dissolution rates, causing the convex parts to It dissolves preferentially over concave parts and can remove rough surface roughness and obtain a smooth finish ranging from an average of several microns to tens of microns. The advantage of this polishing method is that the equipment is simple and only requires a container to hold the solution. It can handle thin tubes, parts with deep holes and complex shapes, and has high production efficiency. The disadvantages are obvious: it is not environmentally friendly, has serious pollution, emits a large amount of harmful gases, has a short service life of the polishing solution, and is difficult to regenerate. The polishing effect is not as good as electrolytic polishing.

Chemical polishing process

Comparison of chemical polishing effects of workpieces

4. Electrolytic polishing.

Electrolytic polishing is essentially chemical polishing. The acid solution is put into the electrolytic tank, the workpiece is used as the anode and connected to the power supply, the lead electrode in the electrolytic tank is used as the cathode, and direct current is passed on. Due to the high current of the burrs and oxide scale on the surface of the part, the corresponding dissolution speed in acid solution is fast. This uneven dissolution speed dissolves burrs or oxide layers first, which plays a smooth and polishing role for the entire workpiece. If the surface is too rough, it is not suitable to electrolytic polish directly. It is best to use mechanical polishing to rough finish it once, and then electrolytic polishing can make the surface finish of the parts reach a very high level, and even achieve a mirror-like gloss effect. Some daily products and handicrafts such as decorative hardware, lamps, kitchen and bathroom supplies made of stainless steel, aluminum alloy, and zinc alloy can be electropolished to obtain a satisfactory surface effect. The advantage of electrolytic polishing is that it is suitable for processing parts with special-shaped and complex surfaces, some parts that cannot be mechanically polished, and internal deep holes, thin tubes, gaps, and dead corners. It has high production efficiency and good polishing effect. The disadvantages are the same as chemical polishing: serious pollution, poor safety, unfriendly to the environment, complicated preparation of electrolytic acid, short service life, and difficult regeneration. It is only suitable for polishing steel, aluminum, copper, nickel and various alloys.

Electrolytic polishing process

Comparison of surface effects of electrolytic polishing workpieces

5. Plasma polishing.

Also called nano-polishing, it is a new environmentally friendly polishing process that can be called a polishing artifact. The principle of plasma polishing is relatively complex. It involves three polishing mechanisms. One is the tip discharge effect: raised parts such as surface burrs have low resistance and are easily broken down in a high-voltage electric field, forming discharge channels. The burrs are dissolved and sharp edges are formed. The corners are rounded and the flatness is improved; the second is the particle bombardment effect: the polishing solution and the workpiece are instantly short-circuited, causing a large amount of heat to vaporize the polishing solution. When the ions of this gas reach a certain number, plasma is formed. The form of this plasma is very high. When it collides with the surface of the workpiece, the oxide layer on the metal surface will be loosened and decomposed, and the surface will be evenly polished. The third is the gas film blasting scour effect: the plasma gas film surrounding the product is rapidly blasted under the influence of electromagnetic field and high temperature, and the oxide layer on the surface of the workpiece is peeled off under the action of tangential cavitation force. The combined action of these three effects instantly The surface of the workpiece will be shiny. Nano-polishing can control the dimensional accuracy of the workpiece within 0.002mm, and the roughness can reach Ra0.01. The polished product has improved smoothness, precision, hardness and durability. It is widely used in the field of fine polishing of high-end products, such as the furniture, bathroom and tableware industries. : handles, handles, faucets, copper parts; glasses industry: glasses frames, glasses frames; aerospace manufacturing: aircraft engine blades; medical device manufacturing: titanium alloys, stainless steel instruments and other fields.

The advantages of plasma polishing are wide application, fast polishing speed (can be completed within ten seconds to two minutes), high precision, good effect, and can achieve electroplating-level mirror effect. Its nano-polishing liquid is very environmentally friendly, and the waste liquid can be discharged directly without causing pollution. The equipment adopts automatic control, which is simple to operate, convenient to maintain and has low labor cost. It can polish some irregular and complex surfaces, dead corners, holes and other parts. It can also produce a passivation film on the surface of the workpiece to keep the surface bright and effectively prevent oxidation. The disadvantage is that the initial investment in equipment is large, and the preparation of workpiece polishing fluids of different materials is complicated. It can only polish conductive materials such as stainless steel, copper, zinc and their alloys. It is not suitable for excessively large burrs, pits, and excessively thick oxide layers. Suitable for polishing medium to large size product parts.

Plasma (nano) polishing machine

Comparison of plasma (nano) polishing workpiece effects