Description

High quality walnut abrasive media for surface finishing and polishing

Walnut shell polishing abrasive media are mainly used in vibratory bowl, centrifugal disc, centrifugal barrel, and tumbling polishing and finishing industries. As a main Mirror Polishing Media, it is used in conjunction with mass finishing machine to perform surface treatments such as adding luster and brightening to the surface of workpiece products.

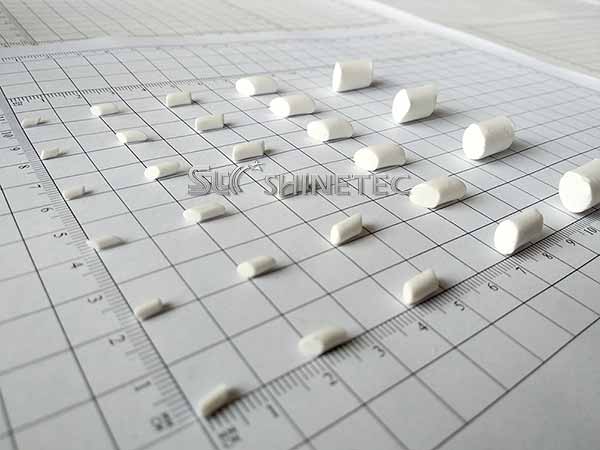

Walnut shell is a soft plant abrasive media formed by crushing and screening dried walnut shells into irregular particles with a particle size of 0.1-8mm. It has good durability and softness, uniform structure, suitable hardness, and toughness. Good, strong water absorption, good wear resistance and other advantages。Mixed with other ointment polishing materials, it is suitable for products that have higher requirements for surface roughness and brightness. The processed workpiece surface can achieve a mirror-like polishing effect. The irregular particle shape has various edges and corners, which can fully reach the corners, gaps, pits and other hard-to-reach parts of the workpiece.

Walnut shell abrasive media have strong water absorption. In the polishing process, they are also suitable for the drying process before the surface treatment of workpieces. When used together with a vibration dryer, they can quickly absorb the remaining moisture on the surface of the workpiece, and can also erase minor scratches and water marks on the surface.

Walnut shell abrasive media can meet the finishing and polishing needs of products in the following industries:

Mechanical accessories, plastic products, auto parts, 3C digital, metal casting, electronic devices, medical equipment, hardware parts, kitchen supplies, aerospace, 3D printing, textile workpieces, powder metallurgy, electrical components, mint industry, jewelry, instruments Instruments, handicraft accessories and other industries.

It is especially suitable for deburring, polishing, drying processing of gold and silver jewelry, golf clubs, watches, hairpins, glasses frames, buttons, electronic components, auto parts, and magnetic materials.