Description

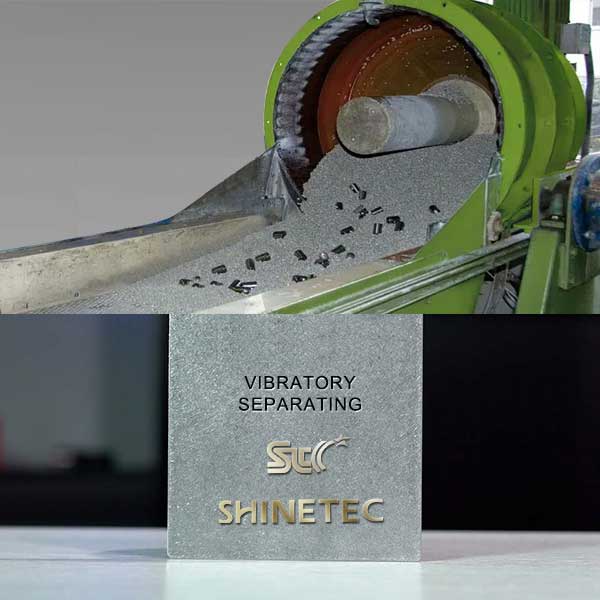

Vibratory Separator

Vibratory separator, also called vibrating screens or linear vibration separating machines, use the excitation force of a vibration motor to drive the abrasive media and workpieces to oscillate on the screen. Since the screen plate has a certain inclination, the materials move forward in a straight line at the same time, so that the workpiece and the tumbling media are automatically separated from the screen. The workpiece can be left on the screen, and the abrasive media falls from the screen holes into the discharge chute below. It can also be that the abrasive media is left on the screen, and the workpiece falls from the screen holes. Fall into the discharge chute. Depends on the size of the abrasive media and workpiece. The abrasive media and the workpiece have independent outlets respectively, and the screen can also have one or more layers to facilitate multi-stage screening.

Universal wheels can be installed on the feet of the separator to increase the mobility of the machine.

The screen is removable and replaceable. If you need to separate workpieces of different sizes, you can replace the mesh with different mesh sizes.

This is a highly versatile auxiliary equipment that greatly improves the screening efficiency of finishing parts and abrasives media. It can be used alone or integrated into a unit with a higher degree of automation to be used in conjunction with other finishing machines on the automatic production line.

Optional:

1. Independent control box to protect the motor and adjust the vibration amplitude.

2. Multi-layer screen, which can be configured with various screens according to the size of the objects to be screened.

3. The flushing device can be configured according to customer needs.

4. The size and hole diameter of the screen plate can be customized according to customer needs.