Description

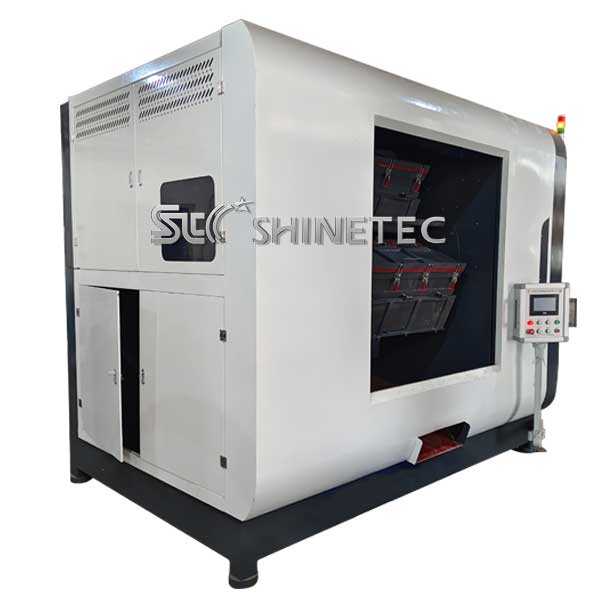

High-speed large centrifugal multi-divider mirror polishing machine

High-speed, large-capacity, multi-divider centrifugal barrel mirror polishing machine, also known as centrifugal high-speed mirror polisher, is a machine that installs four large split barrels on a planetary rotating turntable to generate a strong centrifugal force. The barrels rotate in the opposite direction under the drive of a synchronous belt or gear, causing the mirror polishing media in the barrel to roll and rub against the workpiece at a high speed, cutting and polishing the workpiece surface. It can remove burrs, chamfers, and scales in a very short time, improve surface brightness, remove oil and dirt, and achieve the effect of mirror polishing. Because the machine runs at a very high speed, this model is currently the most efficient batch automatic surface treatment equipment among all tumbling finishing machines.

The abrasive media is in high-speed motion in the barrel, so it can penetrate into the inner wall and gap of the workpiece, which are difficult for general machines to reach. It is particularly suitable for the finishing of the inner and outer surfaces of complex parts with special-shaped holes and cavities, and can also bring a good polishing effect to the inner surface of the product.

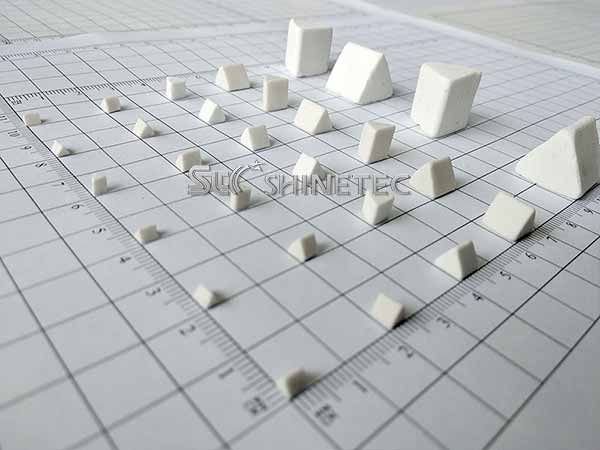

Workpieces that require mirror polishing generally require that during the high-speed operation of the machine, the workpieces must not collide or scratch each other, so as to avoid impact marks, pits, scratches, etc. on the surface that affect the mirror polishing effect. To achieve this goal, the centrifugal polishing barrel of this machine is lined with highly elastic polyurethane rubber (PU), and the interior is designed with dividers that can be assembled at will, forming separate working chamber inside the barrel, placing a single workpiece in an independent chamber, avoiding collision between workpieces, and achieving the function of mirror polishing.

The working barrel cover is designed to achieve two functions: sealing and heat dissipation, as well as filtering impurities. It is suitable for two processes: dry polishing and wet polishing with water.

Through the combination of the dividers in the barrel, it can be flexibly applied to the finishing and polishing of batches of small and medium-sized parts. During the operation of the machine, the workpiece and the tumbling abrasive media are sealed in the working barrel, so the surface condition of the workpiece cannot be checked at any time during the operation. The polishing effect can only be observed after the barrel is opened after the work is completed.

This mirror polishing machine is equipped with a PLC touch screen control box panel, which can set the operation time, operation speed, forward and reverse rotation of the barrel, inching, timed alarm, operation status statistics and other automated intelligent functions.

Reviews

There are no reviews yet.