Description

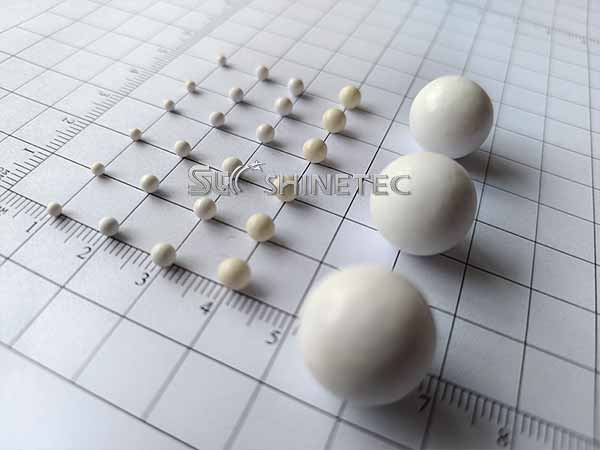

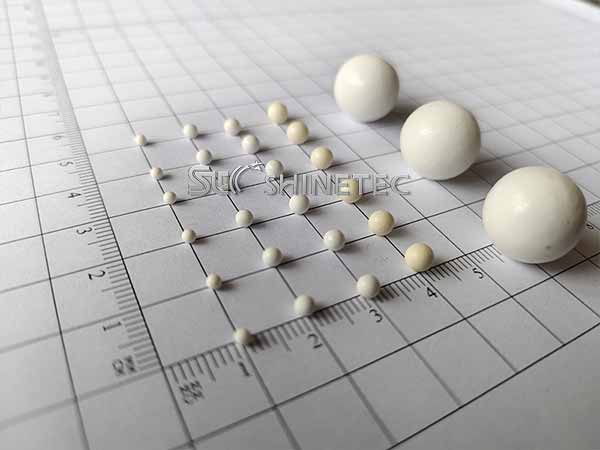

High quality durable high density zirconia ceramic balls, grinding beads for mirror polishing

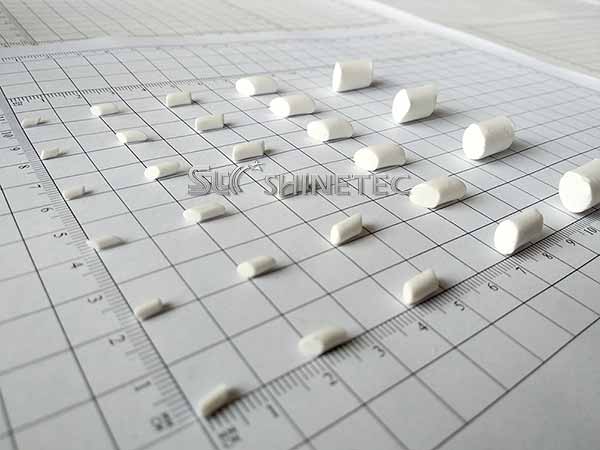

Zirconia spherical mirror polishing media, also called zirconia balls, zirconium beads, are made of high-purity ultrafine zirconium oxide powder as raw materials, yttrium oxide as stabilizer, and are made through special molding process and high-temperature sintering process at about 1200 degrees. The product surface has a pearl-like luster and smooth working spherical surface. Due to the different content of zirconium oxide powder, zirconium spheres with different density can be produced. Super high density zirconium balls are mainly used for ultrafine grinding and dispersant applications of materials requiring zero pollution and high viscosity and high hardness, such as: electronic ceramics, magnetic materials, aluminum oxide, silicon oxide, zirconium silicate, titanium dioxide, food and medicine, pigments, dyes, inks, special chemicals and other industries. Medium to high density zirconium balls are mainly used for grinding of high-end coatings, inks, titanium dioxide and other industries in vertical stirred mills and horizontal ball mills. Medium and low density zirconium balls are mainly used for grinding and dispersion of calcium carbonate, kaolin, zircon sand, titanium dioxide, pigments, dyes, inks, coatings and other industries; they can also be used for metal surface treatment such as sandblasting and shot blasting.

Low density zirconium beads are mainly used in calcium carbonate, kaolin, zircon sand, pigments, dyes, graphite, coatings, metal grinding and polishing and other industries, especially for metal polishing effects. When zirconium balls with low zirconium oxide content are used for mass finishing and polishing, they are mainly used in vibratory/vibrating, centrifugal disc, barrel tumbling finishing and polishing industries. As a high-quality, high-density mirror polishing media, used in conjunction with the tumbling polishing machine to polish and brighten the surface of the workpiece and achieve mirror polishing effects and other surface treatments.

Yttrium stabilized TZP zirconia ceramic balls have the physical properties of high specific gravity, high density, high hardness and high wear resistance at room temperature, as well as high temperature resistance, corrosion resistance, non-conductivity and non-magnetic conductivity. The strength and hardness of zirconia ceramic balls are almost unchanged at 600 degrees, and the thermal expansion rate is close to that of metal materials. The density of zirconia ceramic balls can range from 3.0 to 6.0 g/cm3 according to the content of micropowder, which is far higher than the density of ordinary high-aluminum porcelain polishing media of 2.6 g/cm3. The spherical shape of zirconia polishing balls can make the surface of the polished workpiece have a smoother polishing effect, without leaving scratches on the surface of the product, which is suitable for brightening and enhancing the gloss of some products that have higher requirements on the roughness and brightness of the product surface. The products polished with spherical zirconia polishing media can achieve a more perfect surface quality than other products with sharp angles or sharp edges. The disadvantage is that there is no extension angle and it cannot fully reach the corners, gaps, pits and other difficult-to-reach parts of the workpiece.

Zirconia ceramic balls and polishing beads can meet the mirror finishing and polishing needs of products in the following industries such as brightening and burnishing:

Machinery accessories, automotive parts, 3C digital, metal casting, electronic devices, medical equipment, hardware parts, kitchenware, aerospace, 3D printing, textile workpieces, powder metallurgy, electrical components, coinage, jewelry, instruments, handicraft accessories, etc. Especially in the automated finishing and polishing process of aluminum alloy automobile wheels, zirconia ceramic balls are widely used in the final fine polishing process.

Because we master the core manufacturing technology of zirconia balls, micro polishing beads and other ceramic media, our products have excellent properties such as high hardness and high wear resistance. Less sludge is generated during the finishing process and the polishing efficiency is high. Compared with similar products on the market, the wear resistance can be increased by 3-5 times, and we can provide customers with the most cost-effective high-quality products.

Reviews

There are no reviews yet.