Description

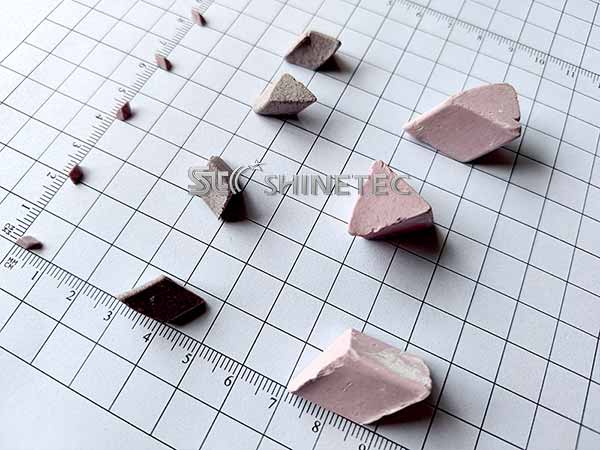

High quality durable angle cut tri-angle pink alumina tumbling finishing abrasive media for surface deburring

Pink fused alumina tumbling media, also called chrome corundum deburring media, ruby alumina vibratory finishing media, are mainly used in vibratory bowl, centrifugal disc, centrifugal barrel, and tumbling polishing and mass finishing industries. As a main tumbling abrasive media,working with tumbling finishing machine, it can perform surface treatments such as deburring, deflashing, descaling, chamfering, and degreasing on the surface of the product parts.

The main component of pink fused alumina finishing media is a mixture of chrome corundum sand and various clays, which undergoes a melting reaction at a high temperature of more than 1000 degrees to form a hard stone-textured product. The sharp hard angle of the angle cut triangle shape is longer and more oblique than that of the straight cut triangle, which can fully reach the corners, gaps, pits and other parts of the workpiece that are not easily accessible by general abrasive media, and polish them inside the machine.

Pink alumina sand is a high-quality grinding abrasive, the main component of which is α-alumina, which is the main component of artificial ruby. It has high density, high hardness, high wear resistance, high strength and good chemical stability. It is widely used in the manufacture of various high-precision grinding tools and cutting tools to meet the requirements of industrial manufacturing for product surface roughness, smoothness and high efficiency. Our tumbling finishing media are divided into heavy cutting, medium cutting and light cutting according to the different cutting forces of the products. The chrome corundum sand used has a particle size of 80 mesh, 120 mesh and 300 mesh respectively, with different product density, which are suitable for different materials and product hardness requirements of the workpiece.

Compared with brown corundum or white corundum tumbling ceramic media, these finishing media have different application ranges due to the different raw material properties of the corundum sand they contain. Chrome corundum has better high temperature resistance, corrosion resistance and slag erosion resistance, and is suitable for high temperature and highly corrosive environments; while white corundum performs better in finishing metal materials with high tensile strength. Cr ions are introduced into chrome corundum to improve the toughness of the abrasive. Its toughness is higher than that of white corundum, while its hardness is similar to that of white corundum. It is suitable for processing materials with greater toughness, such as hardened steel, alloy steel and other workpieces with higher finish requirements. White corundum is suitable for finishing metal parts such as ordinary carbon steel, hard bronze, alloy steel, etc.

Brown corundum ceramic media have a wider range of applications. The products can meet the grinding and finishing needs of products in the following industries such as deburring, deflashing, descaling, chamfering, etc.:

Machinery accessories, plastic products, automotive parts, 3C digital, metal casting, electronic devices, medical equipment, hardware parts, kitchen utensils, aerospace, 3D printing, textile workpieces, powder metallurgy, electrical components, coinage, jewelry, instruments, handicraft accessories, etc.

Because we master the core manufacturing technology of chrome corundum tumbling media, our products have excellent properties such as high hardness and high wear resistance. Less sludge is generated during the grinding process and the grinding efficiency is high. Compared with similar products on the market, the wear resistance can be increased by 3-5 times. We can provide customers with the most cost-effective high-quality products.

Reviews

There are no reviews yet.