Description

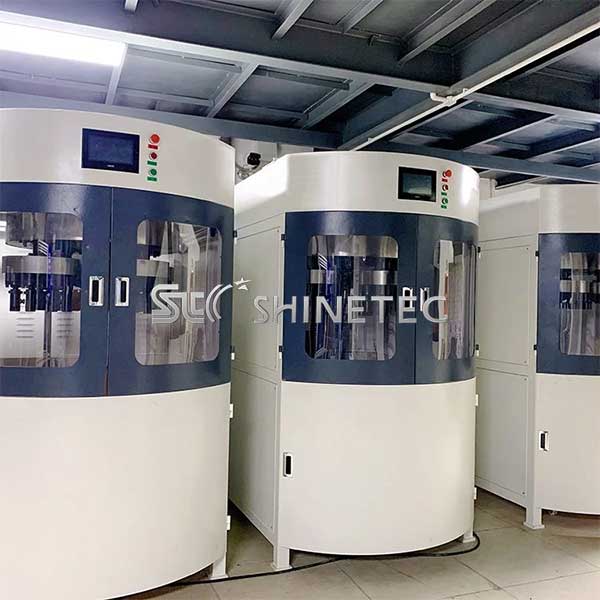

Environmentally friendly drag-type automatic mirror polishing machine

The drag mirror polishing machine, also known as the drag mirror polisher, drag finisher, is operated by installing four small turntables on a large turntable driven by a speed regulating motor. Each small turntable is equipped with a hanging chuck of varying numbers. The large turntable revolves while driving the small turntable to rotate, so that the product workpiece hung on the chuck rotates at high speed in the abrasive media bowl below, driving the abrasive media to perform strong cutting on the surface of the workpiece, thereby achieving deburring, chamfering, passivating, descaling, degreasing, finishing in a very short time, improving the surface brightness and achieving the effect of mirror polishing. The abrasive bowl can be filled with a strong cutting force finishing media, or mirror polishing media, and different polishing requirements can be achieved by replacing the abrasive media. Because in most cases, the bowl is filled with walnut shell chip, corn cob chip, polymer resin media and other abrasive media that do not require water, and no large amounts of sludge or wastewater are generated, this machine is also generally called an environmentally friendly dry mirror polishing machine.

Workpieces that require mirror polishing generally require that they should not collide or scratch each other during the high-speed operation of the machine, so as to avoid impact marks, pits, scratches and other phenomena that affect the mirror polishing effect. To achieve this goal, the workpieces to be polished are hung on independently operated suspension rods by quick-release chucks, forming an eight-shaped spiral motion in the abrasive bowl to avoid collisions between workpieces and achieve the functions of passivation, finishing and mirror polishing of the workpiece surface.

The drag mirror polishing machine, through the combination of different chucks, abrasive media and processes, is widely used in bathroom polishing, tool edge passivation, polishing after coating; high-precision finishing and polishing of jewelry, accessories, etc.; mirror finishing and polishing of watch cases, watch straps and medical devices. It is also widely used in the carbide tool industry:

1. Rounding and passivation of tool edges: tidy up surface defects, round sharp corners, and extend tool life.

2. Finishing and polishing of tool cutting grooves: improve the surface finish of workpieces, deal with surface edges and burrs, and increase tool cutting speed.

3. Polishing after coating: the droplets left after tool coating are removed through finishing and polishing to increase cutting speed.

The main shaft of the machine adopts three-level linkage, which can be inched forward or reverse according to needs, and the speed is adjustable.

The PLC programmable controller is used to control the operation process, which can be fully automatic super-finishing according to the set program, or manually operated. Equipped with an LCD touch screen visual operation human-machine interface to effectively understand the equipment and manage the operating status.

The loading rod adopts a spring clamp with fast clamping and fast unloading functions.

Equipped with two abrasive bowls, automatic abrasive media switching.

The overall design structure of the equipment is reasonable, with low noise, and no obvious environmental and safety hazards.

Reviews

There are no reviews yet.