Description

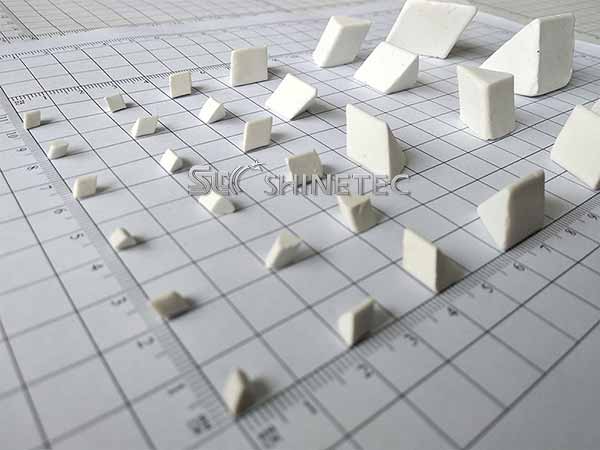

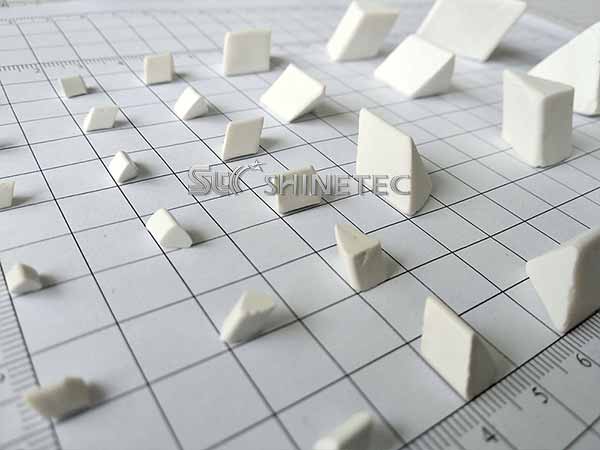

High quality durable angle cut tri-angle tumbling abrasive porcelain media for surface precision polishing

Angle cut tri-angle ceramic porcelain media, also called high-alumina ACT vibratory polishing media, are mainly used in vibratory bowl, centrifugal disc, centrifugal barrel, and tumbling polishing and mass finishing industries. As a high quality tumbling ceramic media,working with tumbling finishing machine, It can perform brightening and burnishing on the surface of the workpiece and at the same time add luster and brightness.

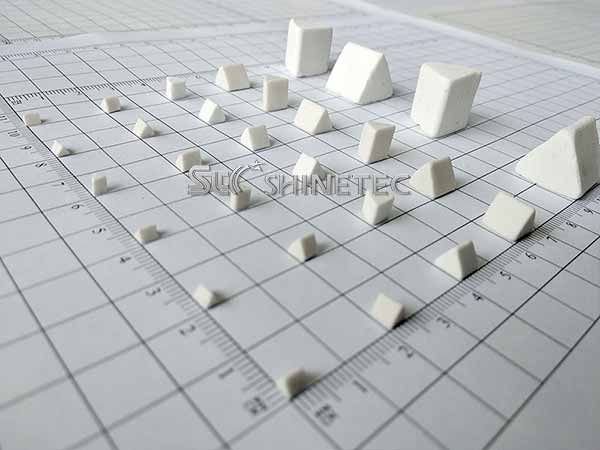

The main component of high-alumina porcelain polishing media is a mixture of alumina powder and various clays, which undergoes a melting reaction at a high temperature of more than 1,000 degrees to form a product with a hard stone texture. The sharp hard corners of the angle cut triangle shape can reach the corners, gaps, pits and other parts of the workpiece that are not easily accessible to general abrasive materials, and are polished together with the chemical compound liquid inside the machine.

The alumina content of high-alumina porcelain polishing media is very high, it can reach about 50% . It has the characteristics of high density, high mechanical strength, good abrasion resistance, high temperature and high pressure resistance, low water absorption and stable chemical property. Can withstand the corrosion of acid, alkali and other organic solvents, is an economic, widely used non-metallic polishing media, with polishing machinery and polishing liquid, in order to meet the requirements of industrial manufacturing for product surface brightness and high efficiency. The particle size of alumina powder used is about 1500 mesh, and the product can have different density and specific gravity by using different clay composition ratio and sintering temperature, apply to the different materials of the workpiece and product hardness requirements.

High-alumina porcelain tumbling media can meet the polishing and brightening needs of products in the following industries:

Mechanical accessories, plastic products, auto parts, 3C digital, metal casting, electronic devices, medical equipment, hardware parts, kitchen supplies, aerospace, 3D printing, textile workpieces, powder metallurgy, electrical components, mint industry, jewelry, instruments Instruments, handicraft accessories and other industries.

Because we have mastered the core manufacturing technology of high-alumina porcelain tumbling media, our products have excellent properties such as high hardness and high wear resistance. They produce less sludge during the finishing process and have high polishing efficiency. Compared with similar products on the market, our products are more durable. The durability can be improved by 3-5 times, which can provide customers with the most cost-effective and high-quality products.