Description

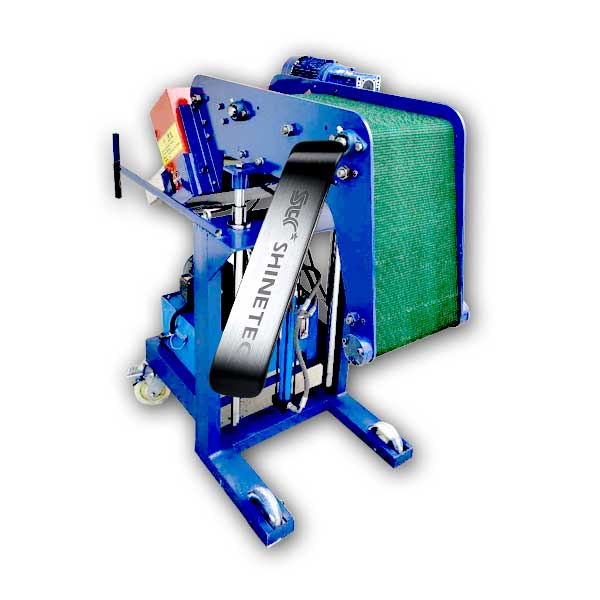

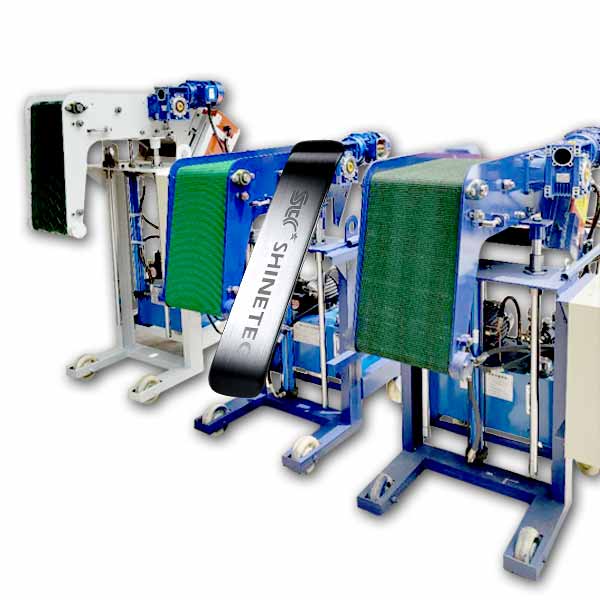

Magnetic Separator

The magnetic separating machine is an auxiliary screening equipment that uses magnetic force to absorb the workpieces from the working tank of the finishing machine onto the conveyor belt and output the workpieces at the discharge port. There are two types: vertical and horizontal.

The vertical magnetic separator is an ideal sorting device used in conjunction with the vibratory finishing machine. But it cannot be used in centrifugal barrel, centrifugal disc, and barrel tumbling machines. However, horizontal magnetic separators can be applied to the above models.

Unlike vibratory separator, magnetic separating machines can start the screening process immediately while the machine is running. The tumbling abrasive media does not need to be taken out from the machine. When the workpiece is turned over in the working tank to the top of the tumbling media, the workpiece can be quickly absorbed from the working tank to achieve the separation effect of the workpiece and the tumbling media. The vibratory separator requires the tumbling media and workpieces to be poured into the screen before it can be operated. After the separating is completed, the media need to be recycled and poured into the finishing machine, which will consume too much working time. Therefore, the screening efficiency of the magnetic separator is much higher than that of the vibrating separator. However, the vibrating separator can be applied to all finishing machine models.

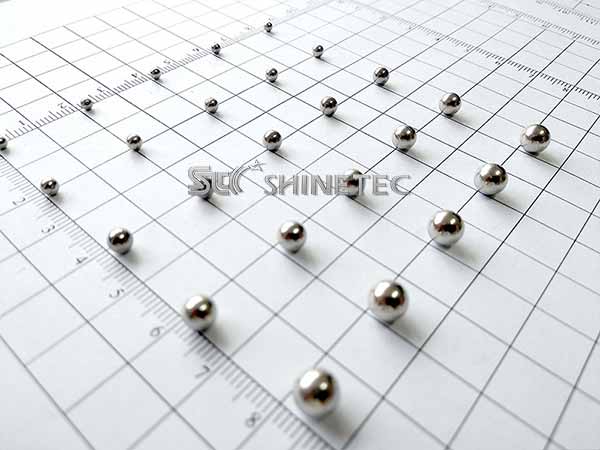

Due to magnetic adsorption, this machine is only suitable for product parts that can be adsorbed by magnets.

The discharge port of the magnetic separator has a demagnetization zone, which can remove the magnetism of the workpiece to prevent the product from agglomerating due to the influence of magnetism.