- 1. What is 3P ceramic media?

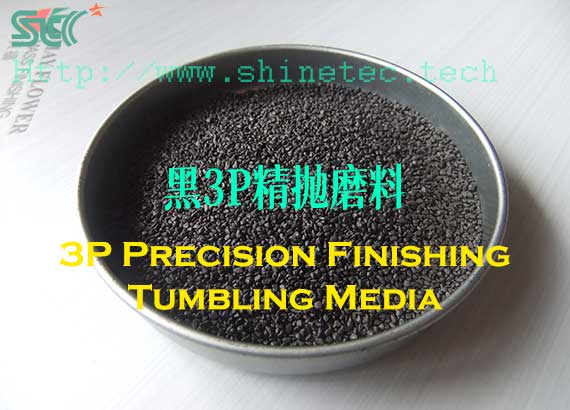

- 3P ceramic media, also known as black 3P tumbling media and G3P precise polishing media, is a random and irregular granular abrasive with a black surface. It is mainly used in bearings, tableware, medical equipment, daily hardware, tools, textile accessories, oil pumps, and pneumatic components, powder metallurgy, automobiles, motorcycles, bicycles, toys and crafts, sewing machines, optical instruments, wind instruments, instrumentation and other industries, deburring, descaling and other finishing processes for precision hardware parts and products, while achieving a mirror polishing effect. A new type of artificial polishing media.

- 2. What is the use of 3P ceramic media?

- 2.1 The main function of 3P ceramic media is to combine finishing and polishing. While cutting, it can polish the surface of product parts to improve the brightness and gloss of the surface. The ordinary polishing process generally requires at least two processes to complete the surface polishing process. The first is the process of rough finishing to remove burrs and scale, and the second is polishing brightness. Especially for some precision parts, many require three processes. Rough grinding + fine finishing + polishing, 3P ceramic media can be completed in only one process. It is indeed a fast and high-quality tumbling polishing media.

2.2 3P ceramic media is an irregular granular shape that can penetrate into hard-to-reach parts such as product workpieces and cross-holes, grooves, dead corners, gaps, etc., and can perform all-round finishing and polishing of the internal and external surfaces of the product. - 3. What is the difference between 3P ceramic media and other abrasive media?

- 3P ceramic media is made from crushed cylindrical or ball abrasives. It is a granular tumbling polishing media with multiple irregular sharp corners. The abrasive sand with cutting force contained in 3P ceramic media is mainly chromium corundum ultrafine powder, which is sintered through high-temperature melting reaction with metal binders. The hardness of this kind of abrasive material is very high, and its density is far higher than ordinary high-alumina porcelain media and high-density porcelain tumbling media, reaching 3.6 g/cm3, which is far more than high-alumina porcelain polishing media and high-density porcelain polishing media. Chrome corundum ultrafine powder acts on the surface of product parts. It is an abrasive material with light cutting force. After cutting, the ultrafine powder can clean the surface of fine burrs, dirt, oxide scale, etc., restoring the original luster of the part material. It forms a low-roughness, delicate product surface with high smoothness. It has excellent surface effects for some high-hardness alloy product parts, such as precision bearings.

- 4. What are the specifications of 3P ceramic media?

-

Item Specification 3P-4 4-6 mm 3P-6 3-4.3 mm 3P-8 2.3-3.4 mm 3P-10 1.7-2.4 mm 3P-14 1.2-1.7 mm 3P-16 0.8-1.4 mm 3P-24 0.6-1.0 mm 3P-28 0.4-0.8 mm 3P-30 0.2-0.6 mm 3P-32 0.1-0.4 mm - 5. Do my product parts need to be polished with 3P ceramic media?

- Generally speaking, 3P ceramic media are suitable for polishing some precision parts and high-hardness alloy product workpieces. If your product parts need to remove small burrs, thin oxide scales, and rust spots, and also need a shiny surface close to mirror polishing, 3P abrasive media are the most suitable finishing and polishing materials. It can be finished and polished in one go.

Of course, using ceramic deburring media with high-alumina porcelain media, high-density porcelain polishing media or stainless steel media can also achieve a bright surface effect. The disadvantage is that it requires additional finishing processes, which is labor-consuming and time-consuming; in addition, the particle size in the powder of ceramic deburring media is far greater than that of chromium corundum micro powder in 3p media, the surface roughness after polishing is higher than that of 3P precision media, and the surface finish is not as good as that of 3P ceramic media.

Finally, for the polishing process, the density of 3P ceramic media is higher than that of high-alumina porcelain media or high-density porcelain media, and the brightness and smoothness after polishing are also better than ordinary ceramic polishing media. - 6. Is 3P ceramic media expensive?

- The prices of 3P ceramic media with different specifications and sizes are also different. One principle is that the smaller the media, the more expensive it is. The price of 3P ceramic media is generally tens of dollars per kilogram, so it is suitable for polishing some precision parts with high added value. Due to the unique product properties of 3P ceramic media, it has specialized and irreplaceable application fields.

- 7. How long is the service life of 3P ceramic media?

- The service life of the abrasive media depends on the size and shape of the product and the specification of the media. The larger the product, the more likely it is that the shape will have edges, sharp corners, edges, burrs, etc. The abrasive wear will be high and the service life will be short.

The higher the hardness of the ceramic media, the greater the wear resistance. The following is a comparison of the service life of 3P ceramic media and other abrasives:

brown corundum ceramic media < white corundum ceramic media < 3P ceramic media < porcelain media < high-density porcelain media < Zirconia polishing media < stainless steel media.

The 3P ceramic media produced by ShineTec are wear-resistant polishing media that have been fired through dozens of sample tests using an exclusive process formula. After wear resistance testing, the wear resistance of our 3P precision polishing media is comparable to the performance of world-renowned manufacturers such as German Roesler and Japanese polishing and abrasive material manufacturer Tipton. If you don’t know where is the best 3P ceramic media, you can take a deeper look at our ShineTec products. - 8. Which finishing and polishing machine is suitable for 3P ceramic media?

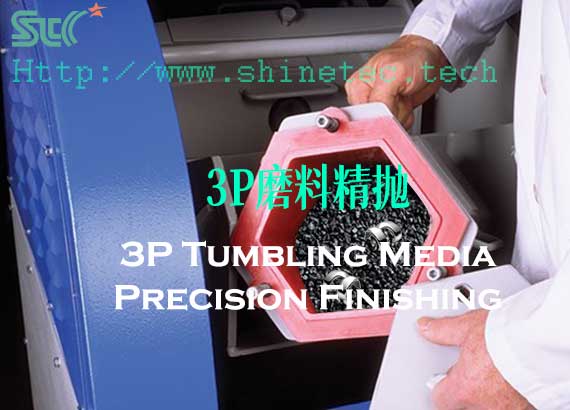

- 3P ceramic media are generally polished using a centrifugal barrel finishing machine. If a vibratory finishing machine is used, due to the small particles of the 3P media, it is difficult to form a good tumbling and rotating action in the machine. The use of centrifugal disc finishing machine will cause the media to get stuck in the gap between the barrel and the chassis, blocking the machine and making it unsuitable for use. The tumbling barrel finishing machine has a small turning force and the media are small, making it difficult to achieve a satisfactory surface polishing quality. The centrifugal barrel finishing machine rotates centrifugally at high speed, and the abrasive media and parts are in a small closed space. It is very suitable for taking advantage of the product characteristics of 3P ceramic media that can both cut and polish.

About Black 3P Abrasive Media

- 1. What is 3P ceramic media?

- 2. What is the use of 3P ceramic media?

- 3. What is the difference between 3P ceramic media and other abrasive media?

- 4. What are the specifications of 3P ceramic media?

- 5. Do my product parts need to be polished with 3P ceramic media?

- 6. Is 3P ceramic media expensive?

- 7. How long is the service life of 3P ceramic media?

- 8. Which finishing and polishing machine is suitable for 3P ceramic media?