What is the centrifugal disc finishing machine?

Centrifugal Disc Finishing Machine

- 1.What is the centrifugal disc finishing machine?

- 2. What is the difference between centrifugal disc finishing machine and other finishing machine?

- 3.Can you tell me how a centrifugal disc finishing machine works?

- 4. What are the benefits of using a centrifugal disc finishing machine to polish parts?

- 5. Is the operating cost of a centrifugal disc finishing machine high?

- 6. What optional configurations are available for ShineTec’s centrifugal disc finishing machine?

- 7.Which model of centrifugal disc finishing machine should I choose?

- 8. What spare parts are available for centrifugal disc finishing machines?

- 9. How does ShineTec ensure the quality of the centrifugal disc finishing machine?

- 10.How to order a centrifugal disc finishing machine?

- 11.What abrasive media can be used in centrifugal disc finishing machine?

- 12.What kind of power supply does the centrifugal disc finishing machine use?

- 13.What is the daily maintenance of the centrifugal disc finishing machine?

- 14.What industries can the centrifugal disc finishing machine be used in?

- 15.Are there any disadvantages to centrifugal disc finishing machine?

- 16.Does the centrifugal disc finishing machine require specially trained technicians to operate it?

- 17.What surface treatments can the centrifugal disc finishing machine perform?

- 18.What are the tumbling media suitable for centrifugal disc finishing machine?

- 1.What is the centrifugal disc finishing machine?

- The centrifugal disc finishing machine is a barrel deburring and polishing finisher with the highest finishing efficiency. Its operating principle is to use a centrifugal rotating disk connected to a motor to drive the working barrel connected to it to rotate at a high speed, so that the ceramic media rotates at high speed together with the product workpiece, but a circle of PU lining tooth tip is specially poured on the inner wall of the barrel. Under the impact of the ceramic media and water flow, a feedback force in the opposite direction is generated, forcing the abrasive media and the workpiece to collide and rub against each other to achieve the surface cutting effect. This kind of grinding efficiency can be 10-30 times higher than other finishing machines, and you can get the surface finishing effect you need in a very short time.

The barrel speed can reach 60-180 rpm, and the speed is controlled by the speed-regulating motor on the machine.

- 2. What is the difference between centrifugal disc finishing machine and other finishing machine?

- The main difference is that the finishing efficiency of the centrifugal disc finishing machine is the highest among all machines. Because the workpiece is always in a continuous cutting process in the abrasive media, this kind of polishing machine takes the shortest time and the fastest speed when finishing.

When the machine is running, the probability of collision between workpieces is minimal because the workpiece and tumbling media are always moving in the same direction.

Suitable for processing small to medium sized products. Because the diameter of the working bowl of this type of machine generally does not exceed 1 meter, and there is a column in the middle of the bowl, so workpieces exceeding 200mm cannot be placed. Even if it can be put into the machine at an angle, the workpiece will be stuck on the inner wall due to the high-speed rotation. If it is often stuck, it will break the PU lining and also cause the product to deform.

The centrifugal disc finishing machine has the strongest cutting force, so it is suitable for finishing some parts and workpieces with long burrs, large flash, and relatively thick oxide scale.

- 3.Can you tell me how a centrifugal disc finishing machine works?

- 3.1 The working barrel of the centrifugal disc finishing machine is open, and the entire barrel can be turned over and tilted downward to facilitate loading and unloading of materials.

3.2 Put the finishing media and product workpieces into the barrel together, turn the barrel over to straighten it, keep the mouth of the barrel upward, then add water and an appropriate amount of finishing liquid. The water surface should not cover the material for about 30mm, and only a small amount of chemical finishing liquid needs to be added. Generally, a 50L machine only needs to add about 30 ml. Note that the volume of materials in the barrel should not exceed 60% of the total volume of the barrel, and then the machine can be started.

3.3 Turn the speed-regulating motor knob on the control panel to gradually adjust the barrel speed from low to high, and finally keep the barrel at the required speed. The entire finishing process is completed automatically, in the meantime, the operator can leave to handle other work tasks without having to stay at the machine.

3.4 After the required finishing time is reached, adjust the speed of the barrel to keep the working barrel rotating slowly, add clean water to the top of the barrel to rinse, open the water flow valve at the bottom of the barrel, let the sewage inside flow out, and inject clean water above to complete the cleaning process.

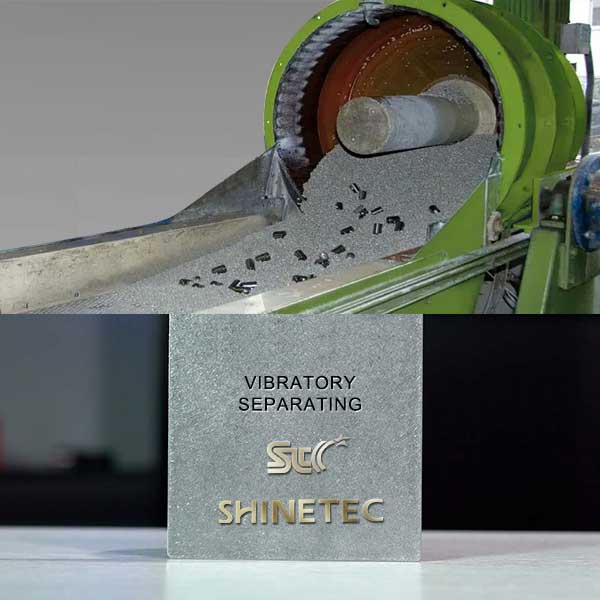

3.5 After cleaning is completed, turn the barrel over and pour out the workpiece and abrasive media. You can also configure a special vibrating separator to separate the abrasives and workpieces automatically, or it can manually screen and pick up the pieces to complete an finishing batch.

- 4. What are the benefits of using a centrifugal disc finishing machine to polish parts?

- Compared with manual polishing, there are definitely many advantages:

4.1 Automatic deburring, deflashing, chamfering. Defects caused during workpiece processing that may cause harm to users can be automatically removed in large quantities.

4.2 Automatically derusting and descaling. Surface problems such as turning lines and mold lines can also be removed.

4.3 Automatic chamfering. Products can be chamfered quickly

4.4 Improve surface finish and increase brightness. Make the product surface smoother and brighter.

4.5 Automatic cleaning and degreasing. It can automatically remove dust, dirt, sludge and other phenomena adsorbed on the surface of the workpiece. - 5. Is the operating cost of a centrifugal disc finishing machine high?

- Compared with manual finishing and polishing, the cost of rotary barrel tumbling machine can be said to be very low.

This is the cheapest automatic finishing and polishing equipment. The one-time purchase cost of the machine can start from several thousand dollars, and it can generally be used for many years. The choice of ordinary abrasive media depends on the actual situation of the product parts that need to be processed, and the price ranges from a few dollars per kilogram to more than ten dollars. etc., buying a few hundred kilograms at a time can generally last for months or even years. The amount of chemical finishing liquid is very small and the cost is almost negligible.

A 50L centrifugal disc finisher can feed about 50 kilograms of product workpieces at a time. The grinding processing time for a batch is generally 30-60 minutes. The direct cost of grinding and polishing when evenly distributed to each product is minimal.

On the other hand, in terms of saving labor costs, the advantages of using centrifugal disc finisher are even greater. As long as workers need to handle it when loading and unloading materials, the machine can be operated unattended, which greatly saves labor costs. - 6. What optional configurations are available for ShineTec’s centrifugal disc finishing machine?

- 6.1 Wear-resistant bucket bottom gasket.

6.2 Bucket electric tilt configuration.

6.3 Quantitative automatic filling of clean water and polishing fluid.

6.4 Built-in automatic separator. - 7.Which model of centrifugal disc finishing machine should I choose?

- You should choose the model of centrifugal disc finishing machine based on the specifications and dimensions of your product parts.

Generally speaking, if the length of your workpiece is less than 50mm, we recommend you use a 50L disc finisher; if the workpiece length is about 50-100mm, use a 120L finisher; if the workpiece length is about 100-150mm, use a 200L capacity machine. For workpieces exceeding 150mm, it is not recommended to use an centrifugal disc finishing machine.

For this disc finishing machine, we also recommend that the mixing ratio of abrasive media to workpiece is about 3:1. - 8. What spare parts are available for centrifugal disc finishing machines?

- The bottom plate of the centrifugal disc, the barrel ring, and the gasket between the barrel ring and the bottom plate are parts that need to be replaced frequently.

Both the disc and the barrel ring have PU linings, which are prone to wear and tear during daily finishing. When the lining of these two parts is found to be damaged, spare parts need to be replaced immediately.

Generally, the barrel ring needs to be replaced every 3-6 months. This mainly depends on the actual usage.

After the gasket is worn, abrasive debris will get stuck in the gap between the barrel ring and the disc, causing the centrifuge disc to get stuck. It is also a key wearing part. - 9. How does ShineTec ensure the quality of the centrifugal disc finishing machine?

- 9.1 Quality assurance of raw materials. Because the lining of the working barrel of the machine is PU, this lining is a wearing part and needs to be replaced regularly. The wear resistance of the PU lining is a key quality indicator. The raw materials of our PU come from major domestic manufacturers and products from Dow Chemical of the United States, so the quality can be guaranteed.

9.2 Reliable motor quality. The motor is a key component related to product quality. The three-phase asynchronous motors used in our barrel deburring machines all come from well-known professional motor manufacturers in Shanghai, and there is no problem with their quality.

9.3 Electrical accessories. All are purchased from domestic first-tier manufacturers such as Chint and Delixi.

9.4 Steel plate profiles. Purchased from Shanghai Baosteel Products.

9.5 Manufacturing Guaranteed. Product production is controlled by skilled workers with many years of front-line production experience, adhering to the spirit of craftsmanship to ensure product quality. - 10.How to order a centrifugal disc finishing machine?

- Please confirm the following basic requirements first:

10.1 Please send samples first and we will conduct samples testing to determine the best finishing and polishing process.

10.2 Evaluate the quantity of your product components and workpieces that need to be processed every day? What surface quality is required?

10.3 Choose the appropriate machine processing capacity, provide the space size of your work area, and determine the machine model.

10.4 Confirm whether additional auxiliary equipment is required, such as vibratory separator, additional wearing spare parts, etc.

10.5 The commonly used power supply for the machine is 380V/3-phase/50Hz. Are there any special power requirements?

After clarifying the above details, you can place an order. - 11.What abrasive media can be used in centrifugal disc finishing machine?

- Tumbling media for rough finishing, fine finishing and polishing:

11.1 The finishing media used for rough finishing is mainly ceramic deburring media, which is divided into heavy cutting force, medium cutting force and light cutting force.

11.2 Finishing media for fine fininishing include white corundum finishing media, chrome corundum finishing media, 3P finishing media, etc. Since the grit size of the micropowder contained in them is very fine, some of which are nearly 2000-3000 mesh, it can continuously polish the workpiece surface. Continuous micro-cutting creates a more delicate surface roughness.

11.3 Polishing media include high-alumina porcelain media, high-density porcelain media (high-alumina porcelain polishing media with an alumina content of more than 95%), stainless steel media, corncob media, walnut shell media, bamboo grain chip, wood grain chip. The main purpose is to improve the gloss and brightness of the workpiece surface. - 12.What kind of power supply does the centrifugal disc finishing machine use?

- In China, it is generally 380V/3-phase/50Hz.

- 13.What is the daily maintenance of the centrifugal disc finishing machine?

- Like other finishing machines, routine maintenance of centrifugal disc finisher is crucial to extending the service life of the machine. Routine maintenance includes the following:

13.1 Check the PU lining on the inner wall of the centrifuge barrel. Daily use of the machine will cause wear and tear on the PU lining in the barrel. You need to regularly check whether there are holes in the PU lining on the inner wall. Are there any defects in the ridges? If damaged, the barrel ring needs to be replaced.

13.2 Before each start, check whether the water added to the barrel is too little or too much. The water surface is generally no more than 30mm above the material. Too little water will cause damage to the surface of the workpiece, the abrasive media will easily break, and the PU lining in the barrel will wear too fast. Too much water will cause the liquid to splash around when the barrel rotates at high speed, affecting the environment.

13.3 Loading capacity of abrasive media and workpiece. We recommend that the ratio of abrasives to workpieces is 3:1. Too little tumbling media will cause collisions between workpieces and damage the product surface; too much abrasives media will reduce the grinding efficiency of the product.

Note that the overall volume of materials in the working barrel does not exceed 60% of the inner volume of the barrel.

13.4 Check for jamming of abrasive debris. The abrasives in the barrel will become smaller and smaller after long-term use. In addition, a lot of debris formed by workpieces and abrasives will be produced during the grinding process. If the width of these impurities is less than 1mm, they may get stuck between the barrel ring and the disc. The gap causes the machine to get stuck and unable to rotate. At this time, you need to shut down the machine, remove the barrel ring, clean the impurities, and restart the machine.

13.5 Water temperature detection. If the centrifugal disc finishing machine runs continuously for more than 2 hours, the temperature inside the working barrel will become very high. Excessively high water temperature will speed up the aging of PU lining, so you need to cool down the temperature in the barrel by replacing the water.

- 14.What industries can the centrifugal disc finishing machine be used in?

- Centrifugal disc finisher are widely used in automotive parts, aerospace, medical equipment, mechanical parts, plastic products, 3C digital, metal casting, electronic devices, hardware parts, kitchen supplies, 3D printing, textile workpieces, powder metallurgy, electrical components, It is widely used in industries such as minting, jewelry, instrumentation, and handicraft accessories.

- 15.Are there any disadvantages to centrifugal disc finishing machine?

- The processing capacity of the centrifugal disc finisher is less thanVibratory finisher and Tumbling barrel finisher. The processing volumes of commonly used models are generally 50L and 120L, so the amount loaded at one time is relatively small.

Due to the small diameter of the barrel, workpieces with a length of more than 150mm are not suitable for finishing and polishing with this model, which may cause deformation and damage to the workpiece.

Since there is a gasket between the working barrel ring and the disc, if the gasket is worn, a gap will appear, causing abrasive debris or impurities to get into the gap and jam the machine. If not dealt with in time, the motor may burn out. - 16.Does the centrifugal disc finishing machine require specially trained technicians to operate it?

- Unnecessary. The operation of this machine is very simple. Just put the abrasive media, workpiece, water and appropriate amount of chemical finishing liquid into the barrel. The machine has a timing function. After starting the machine, the worker can leave to handle other matters. When the set time is up, the machine will automatically shut down. All that is needed is to unload the material and take out the workpiece to complete the finishing and polishing process. Therefore no special technical training is required for employees.

- 17.What surface treatments can the centrifugal disc finishing machine perform?

- 17.1 Deburring, deflashing, chamfering. Defects caused during workpiece processing that may cause harm to users can be automatically removed in batches.

17.2 Derusting and descaling. Surface problems such as turning lines and mold lines can also be removed.

17.3 Improve surface finish and increase brightness. Make the product surface smoother and brighter.

17.4 Cleaning and degreasing. It can automatically remove dust, dirt, sludge and other phenomena adsorbed on the surface of the workpiece. - 18.What are the tumbling media suitable for centrifugal disc finishing machine?

- Depending on the shape, material, specifications and sizes of your parts, you need to choose different types of abrasive media. Abrasives that can be used in the machine are: tumbling deburring media, tumbling porcelain media, high-density porcelain media, polyester media, white corundum finishing media, 3P precise finishing media, walnut shell mirror polishing media , corncob drying media,etc.

Improper selection of abrasives during the finishing process will affect grinding efficiency and may even cause damage to the workpiece.